Artificial Lift Monitoring, Diagnosis and Production Performance Optimization

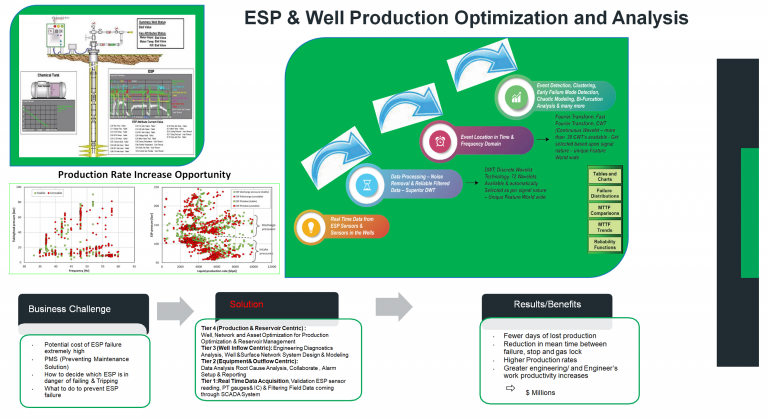

Root Cause Analysis and identification of parameters which are causing ESP malfunctioning, ESP tripping and ESP failure are offered by utilizing advance technology of Machine Learning and Artificial intelligence.

We have POAS Platform (Production Optimization Advisory Solutions), which consists of Advance compositional PVT simulation, Multiphase (3-4 phase) transient well model, Flow Assurance & ESP Monitoring and Optimization, Asphaltene deposits, Wax Deposits, Scale deposits, Sulfur Deposits and other solid deposits modeling and recommending actual solutions to increase well production.

Also, we have Corrosion Modeling & Well Integrity Enhancement Solutions, Diagnosis of higher Watercut & higher GOR, and provide fit to purpose technologies for addressing these challenges.

The technology platform effectively addresses the following major challenges and provides an opportunity to address them effectively.